What is flexo printing? The application process of flexo printing technology

01/08/2025

|

Industry news

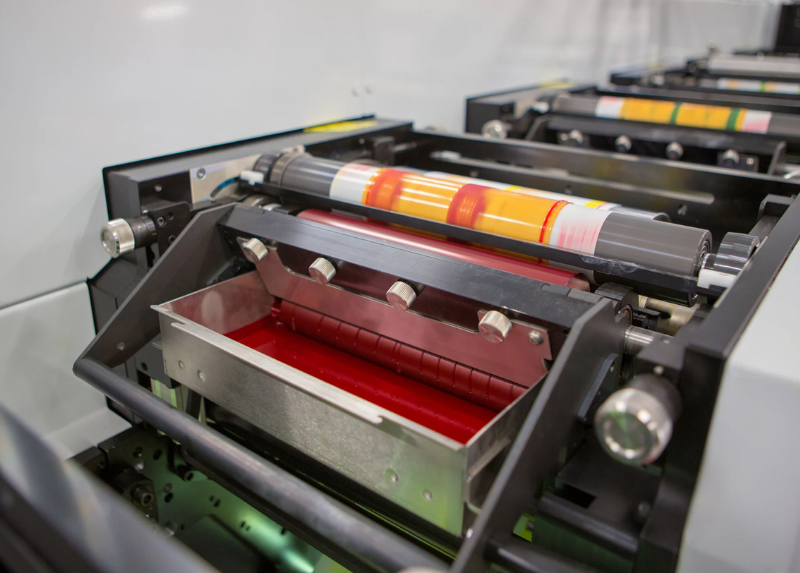

In Flexo (Flexography) is a modern printing technology widely applied in the packaging and labeling industry, allowing printing on various materials such as paper, plastic, metal film, non-woven fabric, etc. With the principle of direct printing using raised plates and a smart ink transfer system via the Anilox roller, it ensures fast printing speed, reasonable cost, and stable quality. Let’s explore the structure of a Flexo machine, its working principle, advantages, and real-world applications!

What is Flexo Printing?

Flexo Printing (Flexography) is an industrial printing technique that uses raised image plates (printing plates) made from photopolymer or rubber, allowing direct printing on many types of materials such as paper, plastic, metal film, fabric, and roll surfaces. It is a modern version of letterpress printing, known for its high-speed capability, cost-effectiveness, and versatility in printing on various substrates – especially in the packaging and labeling industries.

Structure of a Flexo Printing Machine

A Flexo printing machine has a complex structure with key components working together to ensure an efficient printing process:

- Ink Fountain Roller (Metering Roll/Fountain Roller): A cylindrical roller, partially submerged in the ink tray, transfers ink from the tray to the Anilox roller.

- Ink Tray: Contains the printing ink, which can be an open type or enclosed chamber (to control viscosity and reduce solvent evaporation).

- Anilox Roller: A metal cylinder (steel, chrome, or ceramic) with thousands of tiny engraved cells that hold and evenly distribute ink onto the printing plate. This is a core component of the ink transfer system.

- Doctor Blade: Made from steel or polymer, it scrapes excess ink from the Anilox roller to ensure a consistent ink layer and prevent smudging or overflow.

- Plate Cylinder: Holds the raised printing plate (photopolymer or rubber) in place using tape, magnetic force, or locking pins.

- Flexographic Printing Plate: Made from photopolymer or rubber, produced by photochemical methods, CTP, or laser engraving. The thickness and hardness depend on the printed material.

- Impression Cylinder: Made of rubber, it presses the substrate against the printing plate to transfer ink, ensuring sharp image quality.

- Drying System: Dries the ink after each color station to prevent smudging, usually using hot air or UV light (depending on the ink type).

- Quality Control System: Uses scanners or optical sensors to monitor print quality during production.

- Unwind/Rewind Rollers: Handle roll materials, supporting continuous printing.

Operating Principle of Flexo Printing Machine

Flexo printing machines operate based on the direct printing principle, using raised printing plates and a precise ink transfer system:

- Ink supply: Liquid ink is pumped from the ink pan (or a closed system) onto the anilox roller. The anilox roller rotates, partially submerged in ink, filling its tiny cells with ink.

- Excess ink removal: A doctor blade removes excess ink from the surface of the anilox roller, ensuring only the needed amount of ink remains in the cells.

- Ink transfer: The anilox roller contacts the raised printing plate (flexo plate), transferring ink from the cells to the raised elements of the plate.

- Printing: The raised parts of the flexo plate press directly onto the substrate (paper, plastic, etc.) under pressure from the impression cylinder, creating a sharp image.

- Drying: The ink is dried immediately after printing (using hot air or UV) to ensure color fastness and prevent smudging.

Types of Flexo Printing Machines

Flexo printing machines are classified based on design structure, suited for different applications. There are three main types:

Stack Flexo Press

- Structure: Color stations are stacked vertically, each printing unit is independent.

- Advantages: Easy to adjust, clean, and replace materials; supports double-sided printing; high-speed operation; suitable for thick materials like corrugated cardboard or pressure-sensitive adhesive (PSA).

- Applications: Label printing, carton packaging, flyers.

- Limitations: Not ideal for thin or stretchy film materials.

In-line Flexo Press

- Structure: Color stations are aligned horizontally, connected through a common drive shaft.

- Advantages: Flexible handling of both sheet and roll materials; can integrate post-print processes (die-cutting, embossing, foil stamping); suitable for various products.

- Applications: Label printing, carton packaging, flyers.

- Limitations: More complex structure, requires larger space.

Common Impression Cylinder (CI) Flexo Press

- Structure: All color stations are arranged around a single large impression cylinder, with the substrate wrapped around it.

- Advantages: High precision in multicolor printing; excellent color registration, especially for thin materials; fast printing speed.

- Applications: Roll decal printing, plastic film packaging, paper bags.

- Limitations: High investment cost, complex maintenance.

Advantages and Disadvantages of Flexographic Printing

Below is a comparison table between Flexographic Printing and Gravure Printing based on key criteria:

| Criteria | Flexographic Printing |

| Principle | Direct printing using raised plates (photopolymer/rubber), ink is transferred through an anilox roller. |

| Printable Materials | Flexible: paper, plastic, fabric, metal, thin films, carton. |

| Image Quality | Sharp, uniform color, suitable for labels and packaging. |

| Printing Speed | High, up to 300m/min. |

| Initial Investment Cost | Lower, polymer plates are cheaper. |

| Large-Scale Printing Cost | Low, suitable for mass production. |

| Plate-Making Time | Long (several hours to days), not ideal for small quantity printing. |

| Plate Durability | Polymer plates can be damaged by high heat or strong solvents. |

| Flexibility | Flexible, easy to change plates, supports inline finishing (cutting, die-cutting). |

| Environmental Impact | Less toxic, can use water-based inks. |

| Common Applications | Labels, carton packaging, paper bags, roll decals. |

| Disadvantages | Ink may smudge or bleed if doctor blade is ineffective. Not optimal for ultra-fine details. |

Flexographic Plate-Making Process

The plate-making process in Flexo printing is essential for ensuring print quality and includes the following steps:

Step 1 – Design and File Processing

- The design file is created using specialized software like Adobe Illustrator, CorelDRAW, or Adobe Acrobat.

- The file is processed, imposition is done, and CMYK color separations (Cyan, Magenta, Yellow, Black) are applied for accuracy.

- The final file is saved in PDF format.

Step 2 – Data Transfer to Film (CTF – Computer to Film): Digital data is converted into analog film using a film output device. Typically, each CMYK color corresponds to a separate film.

Step 3 – Plate Exposure: The film is mounted onto a plate and placed in an exposure unit. Under UV light, the printable elements (images, text) are etched, while non-print areas remain intact.

Step 4 – Raised Plate Creation:

- The plate is processed to create raised printing surfaces using photopolymer or rubber materials, through photopolymerization, CTP, or laser engraving.

- Plate thickness and hardness are adjusted based on the printing material (paper, plastic, carton).

Step 5 – Mounting the Plate onto the Cylinder

- The finished plate is mounted onto the plate cylinder using adhesive tape, magnets, or locking pins.

- Color register is calibrated to ensure precise alignment of CMYK layers.

Step 6 – Inspection and Test Printing: A test print is run to check quality, and adjustments are made to ink, pressure, and color alignment before mass production.

Types of Flexo Inks and Their Practical Applications

Flexo ink is a liquid-type ink that dries quickly and is categorized into three main types, each suited for specific applications and materials, along with corresponding solvents:

Water-based Ink

- Applications: Printing on paper, carton, food packaging (due to its safety and low toxicity).

- Suitable Materials: Paper, corrugated cardboard, paper bags.

- Solvent: Water (mainly), sometimes mixed with isopropyl alcohol to adjust viscosity.

- Advantages: Environmentally friendly, low cost while still providing relatively high print detail and sharpness, easy to clean. Water-based ink results in a softer texture on the printed surface.

- Disadvantages: Poor adhesion on non-absorbent materials (plastics, metal films), prone to fading or peeling after 5 – 6 months, can blur when exposed to water, and may produce bubbles that affect print quality.

Solvent-based Ink

- Applications: Printing on plastic, metalized film, BOPP, PE, PP, or other non-absorbent surfaces.

- Suitable Materials: Plastic packaging, thin films, labels.

- Solvent: Ethanol, ethyl acetate, or other organic solvents (depending on the type of plastic and drying requirements).

- Advantages: High adhesion on non-absorbent surfaces like plastic (PE, PP, BOPP), metal film, PVC, etc. Excellent water and abrasion resistance, impact and scratch resistance, vibrant colors, and fast drying speed.

- Disadvantages: Solvents evaporate easily, requiring safe working conditions like good ventilation and air filtration systems to prevent fire/explosion hazards and environmental impact. Inhalation of solvent fumes may irritate the eyes, nose, and respiratory system in poorly ventilated environments.

UV-curable Ink

- Applications: Printing on premium labels, food packaging, or products requiring high durability.

- Suitable Materials: Plastic, metal films, coated paper.

- Solvent: No solvent needed; the ink dries under UV light.

- Advantages: Produces sharp images, vibrant colors, high accuracy, and instant drying. Suitable for various materials like coated paper, plastic, metal films, glass, wood, etc. Excellent scratch resistance, waterproofing, and solvent resistance. Ideal for products that require durability, vivid color, and sharp graphics. Less toxic compared to solvent-based inks.

- Disadvantages: UV ink is more expensive than conventional inks. Uncured ink can be harmful to skin and eyes upon direct contact. Short shelf life (~6 months), sensitive to light and temperature.

Flexo Printing Applications in Modern Life

Flexo Printing on Carton Boxes

Flexo printing on cartons is a popular method due to its ability to produce sharp images, rich and even ink coverage using solid colors and an Anilox roller. This technology enables direct printing of product information, logos, and images onto carton surfaces quickly and at a reasonable cost, making it suitable for high-volume production in short timeframes. As a result, flexo-printed products maintain aesthetic quality and help businesses enhance brand identity.

Roll-to-Roll Flexo Printing Machines

Roll-to-roll flexo printing machines are industrial-grade equipment that use flexographic technology to print continuously on rolls of materials such as paper, plastic film (BOPP, PET, PE), decals, labels, or metal films. Operating on a rotary principle, these machines feed material rolls through printing and impression cylinders, ensuring even ink transfer to the surface. With high printing speeds (up to 800 meters/minute) and multi-color printing capability, roll flexo presses are particularly suitable for flexible packaging, plastic bags, and mass production of product labels.

Flexo Printing on Other Materials

Flexo printing is increasingly widely adopted thanks to its versatility across a variety of materials—from paper and fabric to plastics and metal. Beyond carton packaging or decal rolls, flexo can produce a wide range of products that meet different aesthetic, technical, and usage requirements, such as:

- Flexo Printing on Nonwoven Fabric: Used in manufacturing nonwoven bags, masks, and tapes. Helps reduce cost, ensures sharp color, and is environmentally friendly.

- Metal Surfaces: Applied in printing on can lids, tin boxes, decorative metal packaging—providing visually appealing results with good adhesion and durability under harsh conditions.

- Special Decals (paper, plastic, silver foil, destructible, transparent): Used for product labels, warranty seals, tamper-evident labels, and window stickers. Each decal type offers specific features like waterproofing, glossy finish, or transparency.

- Flexo Printing on Cellophane Film: For decorating packaging, creating labels, and increasing brand recognition on consumer goods or gifts.

Notes on Choosing the Right Flexo Ink

- Adhesion: Each printing material has different surface properties. For example, absorbent materials (like paper, carton) require ink with good penetration such as water-based ink, while non-absorbent materials (plastic, BOPP, PE, PET films) need high-adhesion inks like solvent-based or UV inks. Choosing the wrong ink may lead to peeling, fading, or uneven ink coverage.

- Viscosity: Viscosity directly affects ink transfer through the Anilox roller and the uniformity of the print. Ink that is too thin may cause smudging, while overly thick ink can clog systems, create bubbles, or print unevenly. Therefore, adjust ink viscosity properly by adding suitable solvents.

- Environment: For food, cosmetics, or consumer product packaging, prioritize water-based or UV inks due to their low VOC (Volatile Organic Compound) emissions safe for users and eco-friendly.

With high-speed printing capability, stable quality, and versatile applications across many materials, flexo printing has become a trusted and widely used technology across industries. Selecting the right ink and solvent combination ensures optimal results vivid colors, strong adhesion, and long-lasting durability.

Currently, K-Chem is a reputable supplier of high-quality flexographic ink solvents, offering genuine products that meet industrial standards and are environmentally friendly.

Contact K-Chem now for advice on solvents and mixing ratios to optimize performance for your business.

K-CHEM VIETNAM CO., LTD

- Address: N6B Street, Lot F, Phu Chanh 1 Industrial Cluster, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

Email: info@k-chem.vn