Selling Butyl Cellosolve Solvent C₆H₁₄O₂

20/06/2025

|

Industry news

Butyl cellosolve solvent (BCS) is one of the common industrial solvents widely used in many manufacturing sectors due to its good solvency and slow evaporation rate. So, what is BCS solvent? What are its characteristics, applications, and safety precautions when using it? Let’s explore the details in the article below.

What is Butyl Cellosolve Solvent (BCS)?

Butyl Cellosolve Solvent (BCS), also known as Butyl Glycol or 2-Butoxyethanol, has the chemical formula C6H14O2. It is an organic solvent belonging to the ethylene glycol ether group. It is characterized by being colorless, having a mild, ether-like odor, being flammable, and evaporating slowly. BCS is widely used in various industries due to its excellent solvency and surfactant properties.

Physical and Chemical Properties of BCS Solvent

Physical Properties

- State: It is a colorless liquid.

- Odor: It possesses a mild, ether-like, slightly sweet odor.

- Boiling Point: The boiling point is 171°C (340°F).

- Melting Point: It melts at -77°C (-107°F).

- Density: Its density is 0.901 g/cm³ at 20°C.

- Viscosity: The viscosity is 3.3 cP at 25°C.

- Evaporation Rate: It has a slow evaporation rate (0.1 compared to butyl acetate = 1).

- Solubility:

- Completely soluble in water, ethanol, ethyl ether, acetone, benzene, and most other organic solvents.

- Slightly soluble in carbon tetrachloride.

- Vapor Pressure: The vapor pressure is 0.88 mmHg at 25°C.

- Refractive Index: The refractive index is 1.419 at 20°C.

- Flash Point: The flash point is 61°C (142°F, closed cup).

Chemical Properties of BCS Solvent

- Structure: It belongs to the glycol ether group, specifically an ether of ethylene glycol with a butyl group. This molecular structure gives it a unique balance of water and oil solubility.

- Surface Activity: BCS has surface-active properties, meaning it can absorb at oil-water interfaces. This characteristic is beneficial in processes such as cleaning or dispersion, where it helps to bridge immiscible phases.

- Reactions:

- It can participate in esterification reactions with acids to form esters. This is due to the presence of a hydroxyl group (-OH) within its structure.

- It can undergo mild oxidation to form butoxyacetic acid.

- It is not stable in strong acidic or basic environments and may decompose under such conditions.

- Flammability: BCS is flammable. Its vapors are heavier than air and can form explosive mixtures when exposed to an ignition source. This necessitates careful handling and storage.

- Toxicity: It has low acute toxicity. However, prolonged exposure to high concentrations (100-500 ppm) can cause irritation to the skin, eyes, and respiratory tract, or internal organ damage (kidneys, liver) in animals. There is no evidence of carcinogenicity in humans.

Method of Preparing Butyl Cellosolve Solvent

Butyl Cellosolve Solvent (BCS) is primarily synthesized through the ethoxylation reaction between n-butanol and ethylene oxide, catalyzed by an alkali (such as NaOH or KOH). The basic process is as follows:

Main Reaction:

- C4H9OH + C2H4O → C4H9OCH2CH2OH

- In this reaction, n-Butanol (C4H9OH) reacts with ethylene oxide (C2H4O) to produce 2-Butoxyethanol (BCS).

Conditions:

- Temperature: The reaction typically occurs at temperatures ranging from 100-150°C.

- Pressure: The process operates under pressures of 1-5 atm.

- Catalyst: NaOH or KOH is used as an alkali catalyst to increase the reaction yield and efficiency.

Purification:

- The crude product obtained from the reaction is then distilled to separate BCS from impurities, water, and by-products such as diethylene glycol ether. This step is crucial to ensure the purity of the final product.

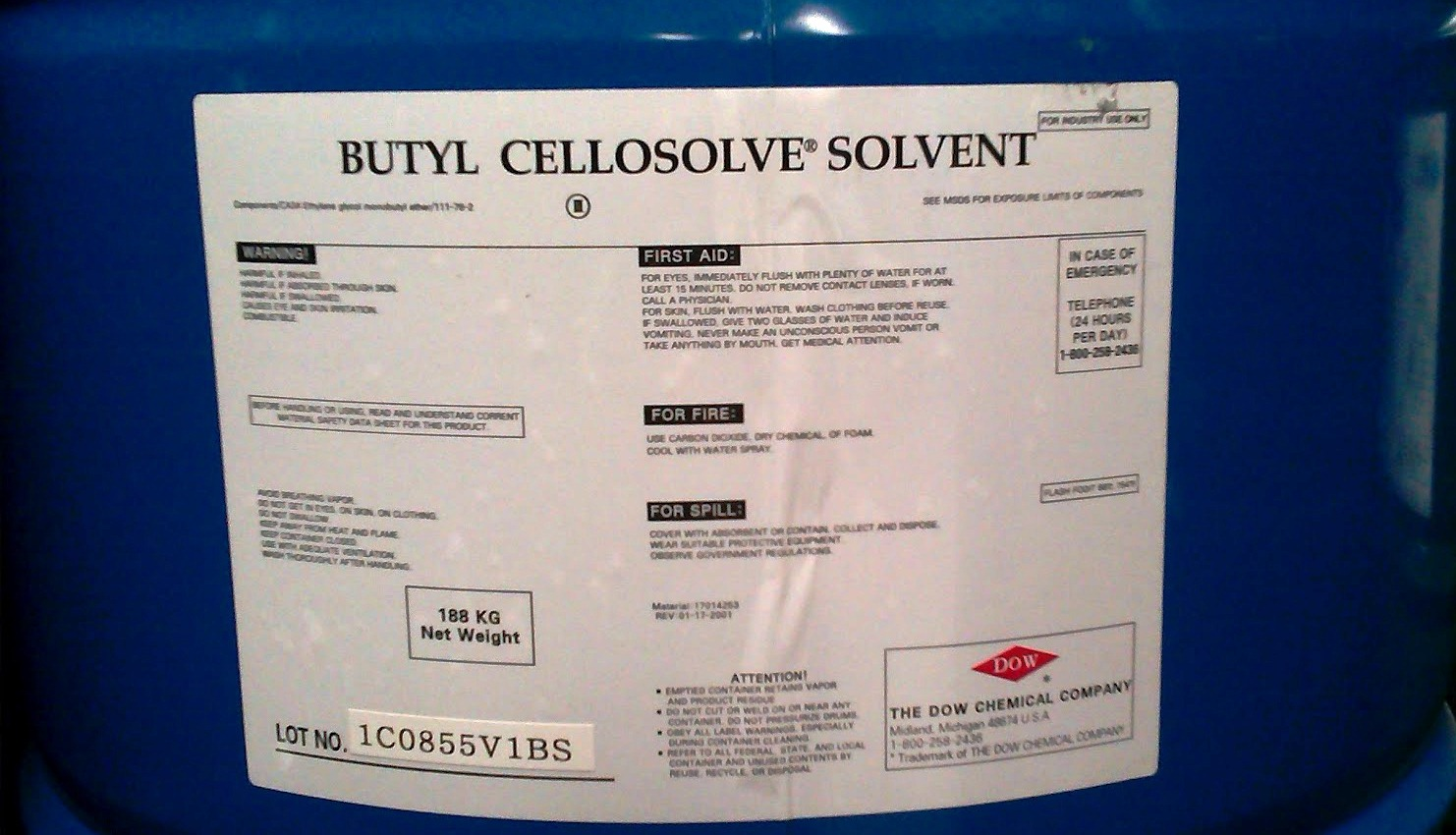

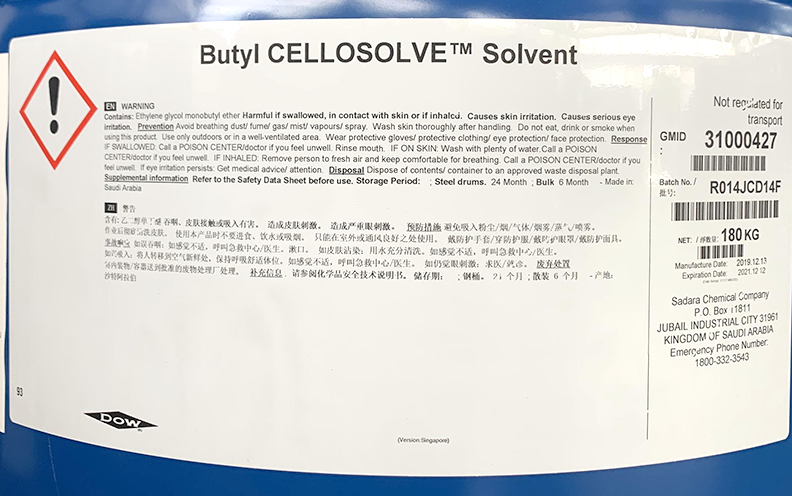

Industrial Scale Production:

- BCS is produced on a large scale by major chemical companies such as Dow Chemical, BASF, or Shell. These industrial processes ensure the production of high-purity BCS, typically >99% pure.

Applications of BCS Solvent

Butyl Cellosolve Solvent (BCS) is widely utilized due to its excellent solvency, slow evaporation rate, and surface-active properties. Its main applications include:

Paint and Printing Ink Industry

- Used as a diluent in paints and coatings, improving their flow and leveling characteristics.

- Acts as an excellent solvent for Nitrocellulose, making it suitable for use in Nitrocellulose paints and oil-based paints.

- Serves as a component in industrial printing inks.

Cleaning Chemicals

- You’ll find BCS in a variety of industrial and household cleaning products such as soaps, dishwashing liquids, and all-purpose cleaners.

- It effectively removes tough stains like grease, ink, and paint due to its good solvency.

Food Industry

- The U.S. FDA has approved BCS as a direct or indirect food additive. For example, it can be used as an:

- Antimicrobial agent

- Defoamer

- Binding agent in food packaging

Textile Dyeing and Printing

- In the textile industry, BCS serves as a leveling agent, helping to reduce streaks and spots on fabrics during the dyeing or printing process, ensuring a more uniform finish.

Oil and Gas Industry

- In the oil and gas sector, BCS is a component in hydraulic fracturing (fracking) fluids.

- It also acts as a stabilizer in oil drilling and a dispersant for oil in spill response efforts.

Plastics and Cosmetics

- BCS helps dissolve synthetic resins in polymer production.

- In the cosmetic industry, it’s an ingredient in some products, such as nail polish and makeup removers.

Other Applications

- Additionally, BCS is used as a solvent in the production of pesticides and herbicides.

- It also serves as a wetting agent in various chemical formulations

Safety Precautions When Using Butyl Cellosolve Solvent

Butyl Cellosolve Solvent (BCS) is a flammable substance and can be harmful if not handled correctly. Here are the essential safety guidelines you should follow:

During Contact:

- Skin: Prolonged contact can cause irritation and dryness. If contact occurs, wash thoroughly with soap and water.

- Eyes: It can cause irritation and redness. Rinse your eyes with clean water for 15 minutes and seek medical attention if needed.

- Inhalation: BCS vapors can irritate the respiratory tract, cause headaches, or nausea. Move the affected person to a well-ventilated area and seek medical attention if symptoms persist.

- Ingestion: Ingestion can be harmful to the kidneys and liver. Call emergency services immediately and do not induce vomiting unless instructed by medical personnel.

While Working:

- Ventilation: Use BCS in well-ventilated areas to prevent vapor accumulation.

- Personal Protective Equipment (PPE): Wear gloves, safety glasses, and a chemical-resistant mask.

- Avoid Ignition Sources: BCS is flammable; keep it away from sparks, flames, or hot surfaces.

- Spill Management:

- Use absorbent materials (like sand or earth) to soak up the spilled liquid.

- Prevent BCS from entering drains or water sources.

Storage:

- Store in a dry, cool, well-ventilated place, away from direct sunlight and high temperatures.

- Keep containers tightly closed to prevent vapor leakage.

- Avoid storing near strong oxidizing agents or acids.

Waste Disposal:

- Do not pour BCS down drains or into the environment.

- Dispose of according to local hazardous waste regulations.

Regulatory Compliance:

- Adhere to chemical safety regulations (e.g., GHS, OSHA, REACH).

- Check exposure limits (PEL/TLV): For example, OSHA sets an exposure limit of 50 ppm (240 mg/m³) over an 8-hour period.

K-Chem – Your Top Source for BCS Solvent at Great Prices and Quality

As a leading chemical manufacturer in Vietnam, K-Chem continuously asserts its position through product quality and modern production technology. We specialize in providing a wide range of chemical products for various industries, including paints, adhesives, inks, agriculture, and many others.

K-Chem is a reputable company dedicated to producing and supplying high-quality BCS solvent along with various other solvents at competitive prices. We ensure all necessary documentation regarding product origin. Additionally, with our team of experienced specialists, K-Chem can create custom solvent formulas to meet the specific requirements of each client. If your business has a need, please contact K-Chem for free consultation and the best possible quote using the information below:

K-CHEM VIETNAM CO., LTD

- Address: N6B Road, Lot F, Phu Chanh 1 Industrial Cluster, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

- EmaiL: info@k-chem.vn