What Is Epoxy Glue Thinner? A Technical Guide to Proper Epoxy Mixing

27/06/2025

|

Industry news

Epoxy adhesive is known for its strong bonding capabilities, excellent load-bearing and heat resistance, and fast curing time, making it ideal for creating durable bonds between different material surfaces. However, to facilitate an easier and faster application process, epoxy adhesives often require additional solvents for thinning. So, what types of solvents are commonly used for thinning epoxy adhesives? What are their functions, and what precautions should be taken during use? These important aspects will be clarified in the article below.

What Is Epoxy Thinner?

Epoxy thinner is a liquid substance used to adjust the viscosity of epoxy adhesive, making the mixing and application processes easier. These solvents help to dilute the adhesive, support uniform mixing of components, and improve penetration into porous surfaces such as wood and concrete. As a result, they enhance the bonding strength and effectiveness of the adhesive.

Functions of Epoxy Thinner

Epoxy thinners play a crucial role during application, depending on the intended use. Below are the main functions when used with epoxy adhesive:

- Reducing Viscosity: Solvents thin the naturally thick epoxy resin, making it easier to mix with the hardener or apply to surfaces. This is especially useful for thin coatings or penetrating narrow gaps.

- Improving Workability: Lower viscosity results in easier spreading, spraying, or pouring of the adhesive, which is suitable for tasks such as surface coating, epoxy painting, or creating protective layers.

- Adjusting Drying Time: Some solvents can slow down the curing process by extending the evaporation time, allowing more time for manipulation before the epoxy hardens.

- Enhancing Wetting Ability: In certain situations, solvents help the epoxy penetrate deeper into porous materials (such as wood or concrete), improving adhesion and bonding performance.

Top 5 Recommended Epoxy Thinners Today

Acetone

Acetone is a colorless, highly volatile liquid with a mild characteristic odor. It is widely used due to its strong dissolving power and fast evaporation rate. This makes it ideal for thinning epoxy or cleaning tools after use.

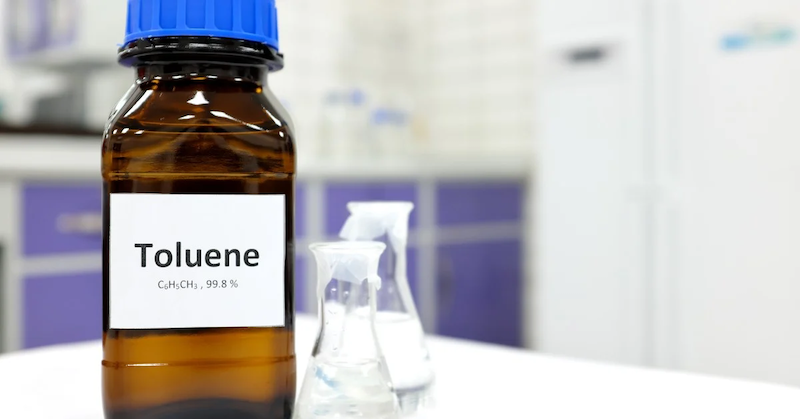

Toluene

Toluene is a colorless solvent with a distinct aromatic odor. It is volatile, insoluble in water, but highly soluble in many other organic solvents. It is commonly used to reduce epoxy viscosity but should be handled with care to avoid affecting the adhesive’s properties.

Xylene

Xylene (also known as Dimethylbenzene) is a liquid, colorless, volatile compound with a mild aromatic scent. Thanks to its excellent dissolving properties, xylene is used to thin epoxy and is widely applied in various industries.

Alcohol (Isopropyl Alcohol)

Isopropyl alcohol is a colorless, volatile chemical compound with a distinct smell. Due to its solubility in both water and various organic compounds, it is occasionally used for cleaning or mild thinning purposes. However, it is not always fully compatible with epoxy adhesives.

Technical Guide to Mixing Epoxy with Solvent for High Efficiency

Step 1: Identify the Purpose of Adding Solvent

Solvents are typically added to thin epoxy, making it easier to apply (e.g., for thin coatings or deep penetration into materials). Make sure you understand the reason for using a solvent and select the right type (commonly xylene, acetone, or isopropyl alcohol, depending on the manufacturer’s instructions).

Step 2: Prepare Tools and Materials

- Epoxy (Part A – resin) and hardener (Part B – hardener)

- Suitable solvent (check epoxy manufacturer’s instructions)

- Measuring cup with accurate gradations

- Stirring stick (wood or plastic)

- Gloves, mask, and safety goggles for protection

- Work in a well-ventilated area

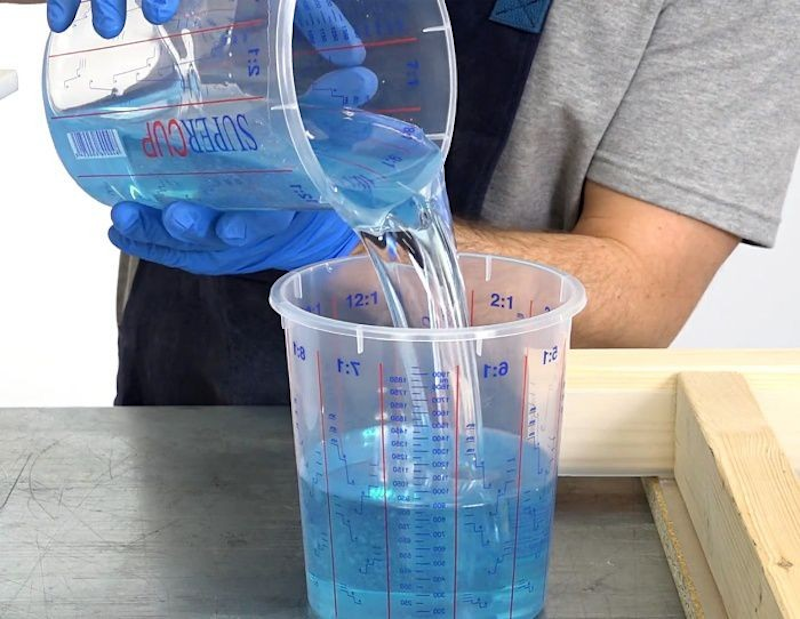

Step 3: Measure the Epoxy and Hardener

- First, mix the epoxy and hardener according to the manufacturer’s specified ratio (usually 1:1, 2:1, or as directed).

- Use the measuring cup for accuracy, then stir thoroughly for 2 – 3 minutes until the mixture is uniform.

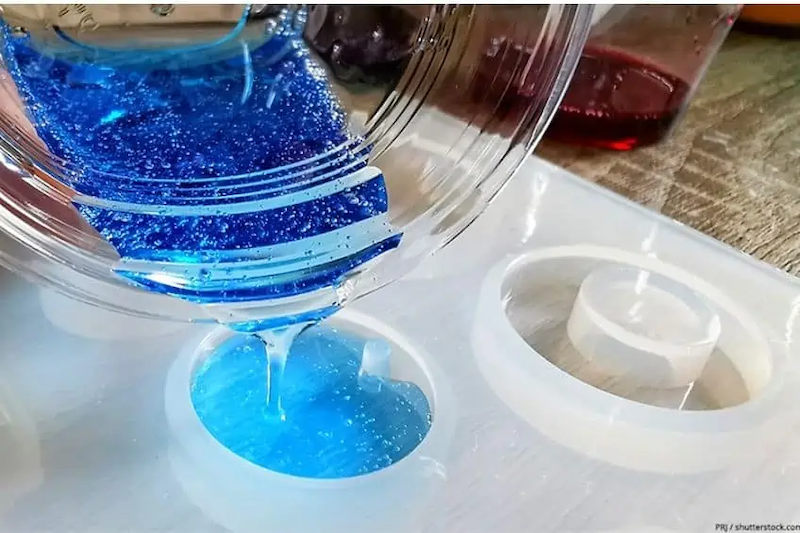

Step 4: Add the Solvent

- After mixing the epoxy and hardener, slowly add the solvent to the mixture.

- The solvent ratio should not exceed 5 – 10% of the total epoxy mixture weight (depending on the epoxy and solvent type). Excess solvent may reduce product quality.

- Stir for another 1 – 2 minutes to ensure complete solvent integration.

Step 5: Check the Viscosity

- Test the mixture on a small surface to check if the consistency meets your requirements (e.g., ease of brushing, good penetration).

- If needed, gradually add a small amount of solvent and continue stirring.

Step 6: Use Immediately

After adding solvent, the working time of the mixture becomes shorter as the solvent may accelerate curing. Apply the mixture immediately.

Important Notes

- Read Manufacturer Instructions Carefully: Not all epoxies are compatible with solvents. Some may lose mechanical properties when diluted.

- Safety: Solvents are flammable and have strong odors always work in ventilated areas and away from fire sources.

- Test Before Full Use: If it’s your first time, test on a small sample to ensure desired results.

Solvent plays a vital role in epoxy application it helps thin the mixture, ensures better blending of components, and enhances penetration. Technicians must not only understand its importance but also know the correct purpose and technique for mixing.

Contact K-Chem – A trusted supplier of bulk epoxy solvents or ready-mixed epoxy products. Reliable quality at reasonable prices. Leave your information or get free consultation from our team of experienced experts via the contact details below:

K-CHEM VIETNAM CO., LTD

- Address: N6B Road, Lot F, Phu Chanh 1 Industrial Cluster, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

- Email: info@k-chem.vn