Epoxy Thinner: Role, Application in the Coating Industry

16/05/2025

|

Industry news

Epoxy paint is one of the popular paints in construction and industrial works thanks to its outstanding features such as high durability, corrosion resistance and resistance to strong mechanical impacts. However, to achieve the best quality of epoxy paint, using the right epoxy paint diluent plays an extremely important role. This article will provide detailed information about epoxy paint diluent, helping you better understand this product.

What is Epoxy thinner?

Epoxy thinner is a liquid that can dissolve the ingredients in epoxy paint, helping to adjust the viscosity of the paint, improve the ability to construct and ensure an even, smooth and durable paint layer. This solvent is often used in the process of mixing epoxy paint with additives, creating a mixture that is easy to use and highly effective.

Important Properties of Epoxy Paint Thinner

Chemical Properties

When combined with epoxy paint, epoxy solvents can trigger chemical reactions with the paint’s components. This often leads to clumping, sedimentation, or other issues after mixing.

Solubility

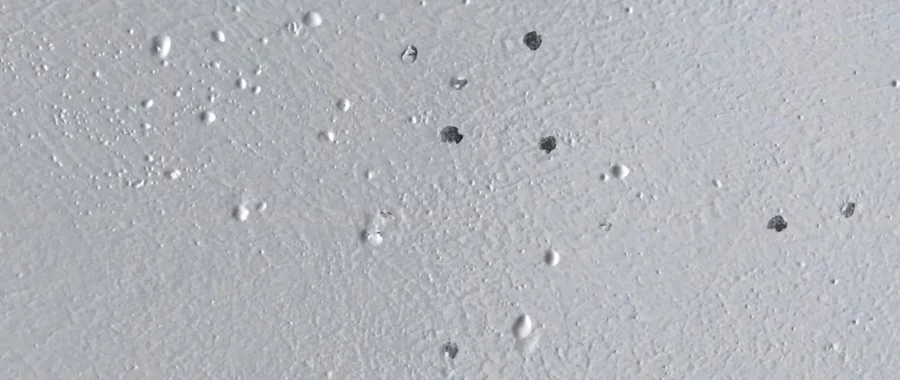

The solubility of each type of epoxy solvent varies significantly. When a solvent is mixed with additives that have low solubility, the resulting paint mixture may form emulsions along with undissolved materials. As a result, during the spraying process, this mixture can cause bubbling, color spotting, and the appearance of tiny clumps on the surface layer.

Purity

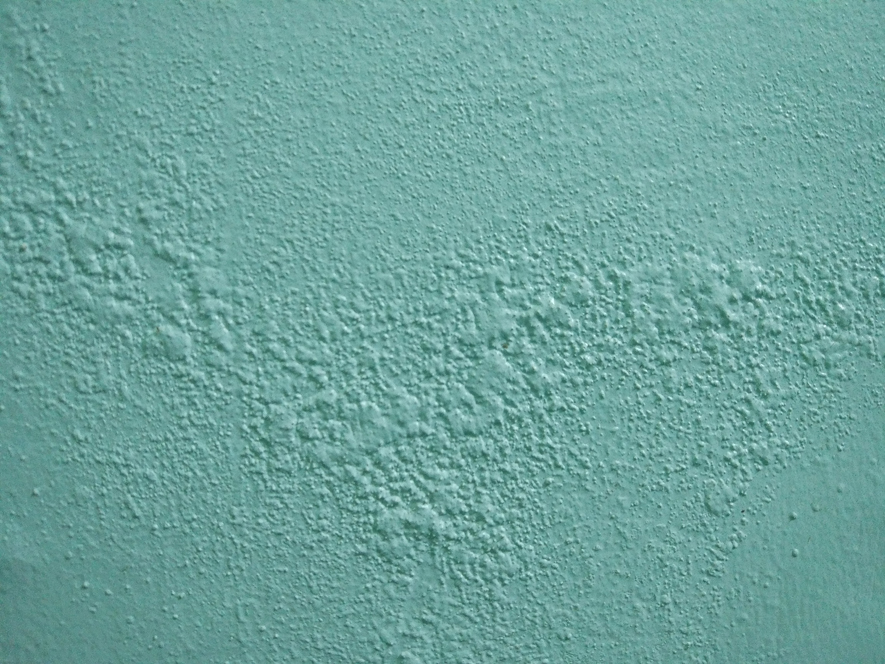

The purity of epoxy paint solvents mostly depends on their origin. This is because solvents without a clear source often contain impurities, which can directly affect paint adhesion. After spraying, the surface may become wrinkled, uneven, lack smoothness, and the paint color may appear inaccurate.

Polarity

The polarity of epoxy solvents affects the solubility of various components in epoxy paint. Non-polar solvents tend to dissolve non-polar substances, while polar solvents dissolve polar substances.

Density

The density of epoxy solvents determines the evaporation rate and the gloss level of the coated surface. In cases where the paint dries quickly but is combined with a high-density solvent, the drying time of the mixture will be extended. Conversely, when slow-drying paint is used with low-density solvent in high-temperature conditions, it can easily cause air bubbles or blistering on the surface coating.

Popular types of Epoxy thinners

There are many different types of solvents used in epoxy paint, depending on the technical requirements and characteristics of each type of paint. Some common solvents are:

Acetone solvent: This is a common solvent that helps thin the paint and reduce viscosity. Acetone also has the ability to clean the surface before painting and remove impurities.

Toluene solvent: This is an organic solvent that can dissolve epoxy compounds well and help increase the durability of the paint layer. However, toluene can be toxic, so it must be used properly and in a well-ventilated environment.

Xylene solvent: This solvent is commonly used to mix epoxy paint, helping to thin the paint and make it easier to apply. Xylene also helps the paint dry faster.

Methanol solvent: Used in epoxy paint formulations that require high permeability, methanol helps increase the adhesion of the paint layer to the surface.

The role of solvents in Epoxy paint

Solvents play a number of important roles in creating the quality of epoxy paint, including:

Adjusting viscosity: Solvents help reduce the viscosity of the paint, making it easier to apply the paint and the paint layer is evenly coated, without air bubbles.

Ability to dissolve components: Solvents help dissolve the compounds in epoxy paint, ensuring that the components are mixed evenly and do not separate.

Increasing durability: Some solvents also help increase the durability of the epoxy paint layer, ensuring abrasion resistance and corrosion resistance.

Supporting the drying process: Solvents also help the paint dry quickly without affecting the surface quality after painting.

How to use Epoxy paint thinner effectively

To use epoxy paint thinner effectively, you need to follow some basic principles:

Reasonable amount of solvent: Adding too much solvent to the paint can reduce the durability of the paint layer, while if there is too little solvent, the paint can be too thick and difficult to apply. You should refer to the manufacturer’s instructions for mixing the correct ratio.

Test before construction: Before painting a large area, you should test on a small surface to check the smoothness and adhesion of the paint layer.

Use in well-ventilated conditions: When mixing epoxy paint with solvents, especially highly volatile solvents, it is necessary to apply in a well-ventilated environment to ensure health safety.

Notes when using Epoxy paint thinner

Health protection: Some solvents can be harmful to health if directly exposed or inhaled. Protective gear such as gloves, masks and goggles should be used when working with solvents.

Do not expose solvents to high heat sources: Solvents are flammable, so avoid exposing solvents to heat sources or direct fire.

Store properly: Solvents should be stored in a cool, dry place and away from direct sunlight. Make sure that solvent containers are tightly closed to avoid evaporation and loss of quality.

Conclusion

Epoxy paint thinner is an important factor in ensuring the quality and effectiveness of epoxy paint. Choosing the right solvent, using it properly and protecting it safely during construction will help you achieve optimal results. If you need to buy solvents or epoxy paint, carefully research the products on the market and choose quality products from reputable suppliers to ensure work efficiency.

If you need to purchase solvents or epoxy paint, please carefully research products on the market and choose quality ones. Contact the information below now to receive a free quote and consultation!

K-CHEM VIETNAM CO., LTD

- N6B Road, Lot F, Phu Chanh 1 Industrial Park, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

- Email: info@k-chem.vn

- Website: https://k-chem.vn