Gravure Ink solvents: Role, Applications, Common Solvents

16/05/2025

|

Industry news

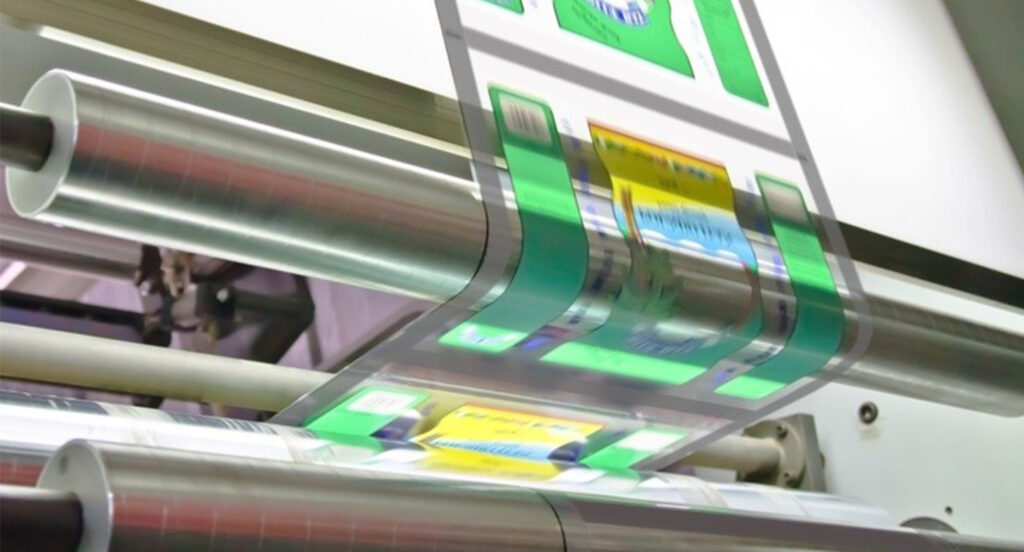

In the printing industry, especially gravure printing, ink and solvents are indispensable factors to create quality printed products. Gravure ink solvents play an important role in adjusting viscosity, improving adhesion, and supporting the printing process to achieve high efficiency. The following article will provide detailed information about gravure ink solvents, helping you better understand this product.

What is gravure ink thinner?

Gravure ink solvents are liquids used to dilute ink, adjust viscosity and improve the workability of ink in the gravure printing process. Gravure ink is commonly used in the packaging and printing industries, especially gravure printing on materials such as paper, plastic, metal, etc. Solvents help the ink to easily print on these surfaces without affecting the adhesion, glossiness or sharpness of the image.

The role of solvents in gravure printing ink

Solvents have several important roles in creating the quality of gravure printing ink:

Adjusting viscosity: One of the main tasks of solvents is to adjust the viscosity of the ink. Ink that is too thick can cause difficulties in the printing process, while ink that is too thin will reduce the quality of the printed image. Solvents help to maintain the right viscosity, ensuring that the ink easily adheres to the material surface.

Improving adhesion: Solvents help the ink adhere better to the material surface, thereby improving the quality of printed products. In particular, with difficult-to-adhere materials such as plastic or metal, solvents help the ink adhere easily and not fade.

Support the drying process: Solvents have the ability to control the drying time of the ink, helping the printing process to take place quickly and effectively. Fast drying saves time and production costs.

Increase durability: Some solvents also help improve the durability of the ink, helping the ink to be resistant to abrasion, scratch resistance and maintain sharpness for a long time.

Popular types of solvents for mixing gravure printing ink

Currently, there are many different types of solvents used to mix gravure printing ink on the market, each type of solvent has its own advantages and applications. Below are some popular types of solvents:

Ester-based solvents: This is a popular type of solvent used in mixing gravure printing ink thanks to its good solubility, effectively reducing viscosity without affecting the quality of the ink. Ester-based solvents also have the ability to evaporate quickly, helping the ink dry quickly after printing.

Ketone-based solvents: Ketone solvents such as acetone, MEK (methyl ethyl ketone) are widely used in the gravure printing industry. They have good dissolving ability of plastics, increase ink adhesion and help the ink dry faster.

Alcohol-based solvents: Alcohol solvents such as ethanol and isopropanol are also used to mix gravure printing inks. These solvents have the ability to dissolve some plastic components in the ink, making the ink easy to apply and adhere well to the material surface.

Hydrocarbon-based solvents: Hydrocarbon solvents have high dissolving ability and the ability to reduce the viscosity of the ink. This type of solvent is used in printing inks that require high durability and good abrasion resistance.

How to use gravure ink solvent effectively

To achieve the highest efficiency in using gravure ink solvent, you need to note the following points:

Mixing the correct ratio: Mixing solvent into ink must follow a certain ratio to ensure ink quality and avoid reducing printing efficiency. Too much solvent can make the ink too thin, while too little solvent will make the ink too thick, making it difficult to apply.

Check the viscosity: Before starting to print, you should check the viscosity of the ink after mixing with solvent. If the ink is too thick or too thin, you need to adjust the amount of solvent to achieve the ideal viscosity.

Use solvents safely: Some solvents can be harmful to health if exposed for a long time, so you need to use protective gear such as gloves, goggles and masks when mixing ink or operating the printer.

Store solvents properly: Solvents should be stored in a cool, dry place and away from heat sources. This helps the solvent not to deteriorate and maintain its effectiveness when used.

Summary of 4 popular rotogravure printing ink solvent

Acetone

- Properties: Excellent solvency, fast evaporation rate, flammable

- Note: Highly flammable, may irritate skin and eyes

Toluene

- Properties: Fast evaporation, good solvent for many resins and dyes

- Note: Toxic; requires well-ventilated working/storage areas. Operators should wear appropriate protective gear (masks, gloves)

Methyl Ethyl Ketone (MEK)

- Properties: Fast evaporation, excellent solvency, low viscosity, forms durable ink film after blending

- Note: Toxic and flammable

Isopropanol (IPA)

- Properties: Fast evaporation, good solvency, relatively low toxicity

- Note: Flammable, may cause skin and eye irritation

Notes when using solvents for mixing gravure printing ink

Protect your health: Solvents can contain toxic substances, so when working with solvents, ensure a well-ventilated working environment and use full protective equipment.

Check the quality of ink before printing: Before starting the printing process, test the ink on a small surface to ensure the required print quality.

Choose the right solvent: Depending on the type of ink and printing material, you need to choose the right solvent to achieve the highest efficiency in the printing process.

Conclusion

Gravure printing ink solvents play an important role in ensuring the quality of ink and the efficiency of the gravure printing process. Choosing the right solvent, mixing it properly and using it in.

Contact the information below now to receive free consultation on gravure ink solvents from K-Chem’s team of trusted experts!

K-CHEM VIETNAM CO., LTD

- N6B Road, Lot F, Phu Chanh 1 Industrial Park, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

- Email: info@k-chem.vn

- Website: https://k-chem.vn