Suggested 4 Types of PET Ink Solvents and Notes on Safe Use and Storage

14/07/2025

|

Industry news

This solvent features high diffusivity with various types of ink, ensuring color quality, stability, and proper drying time, thereby maintaining uninterrupted production. However, what exactly is a PET ink solvent in more detail? Let’s dive into the information below to better understand the role, applications, and precautions for using and storing PET ink solvents.

What is PET Ink Solvent?

PET (Polyethylene Terephthalate) ink solvent is a liquid used to dissolve components, adjust viscosity, and enhance the printability of inks especially for printing on PET materials. These solvents play a crucial role in producing high-quality prints that are durable and aesthetically pleasing over time.

Main Roles of PET Ink Solvent

Dissolving Ink Components

The solvent helps dissolve the ingredients in PET ink, creating a uniform ink mixture that is easy to use and prevents clumping during printing.

Adjusting Ink Viscosity

One of the key roles of PET ink solvent is to regulate the viscosity of the ink, allowing it to flow smoothly and adhere effectively to the printing surface.

Preventing Abrasion and Maintaining Long-Term Aesthetics

PET ink solvents also protect the ink from abrasion, keeping the printed surface shiny and attractive, thereby preserving the product’s long-term visual appeal.

Preventing Ink from Drying Too Quickly Before Printing

Another benefit of PET ink solvent is that it prevents the ink from drying too fast, ensuring smooth printing without clogging issues.

Common Types of PET Ink Solvents

Ethyl Acetate (EA)

- Characteristics: A colorless organic solvent with a mild ester scent and high volatility.

- Applications: Commonly used in screen printing or gravure printing on PET films due to its excellent solubility, enabling quick ink drying and adhesion.

- Advantages: Low cost, low toxicity, and provides a glossy finish to prints.

Xylene

- Characteristics: A colorless solvent with a mild aromatic odor, consisting of three isomers (ortho, meta, para).

- Applications: Suitable for screen and gravure printing on PET film, improving ink adhesion and sharpness.

- Advantages: Fast drying, even application, and easy control of color quality.

Toluene

- Characteristics: A colorless, fast-evaporating solvent with high dissolving power.

- Applications: Commonly used in gravure printing on PET film, especially for packaging products that require quick drying and high color durability.

- Advantages: Enhances ink diffusion and maintains stable color.

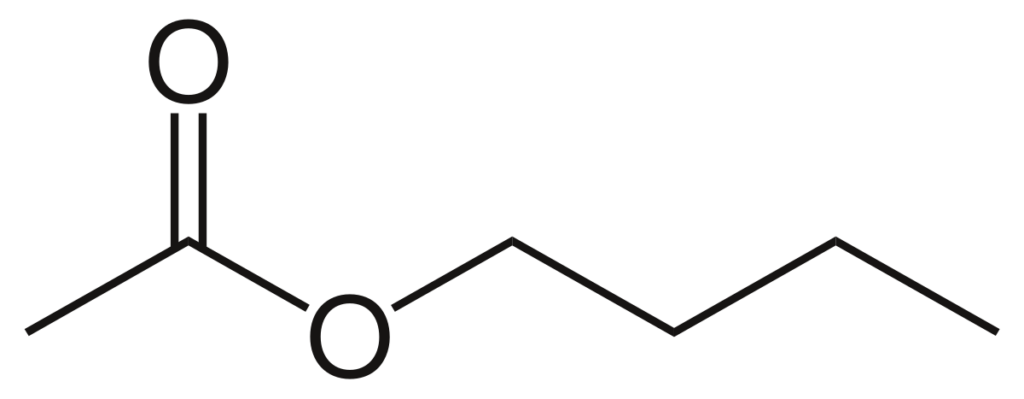

Butyl Acetate

- Characteristics: A solvent with a mild odor and medium evaporation rate.

- Applications: Used in PET ink systems to adjust viscosity and improve adhesion.

- Advantages: Creates smooth ink films and minimizes clogging during the printing process.

Notes on Storage and Use of PET Ink Solvent

- Store the solvent in a dry, cool, and well-ventilated place, away from direct sunlight, to maintain stable solvent quality.

- Ensure safety during use by wearing gloves and protective goggles. Avoid direct contact with skin and eyes.

- Use the correct amount of PET ink solvent as recommended by the manufacturer to avoid affecting ink quality.

- Do not use the solvent past its expiration date, as it may reduce mixing effectiveness and negatively impact print quality.

PET ink solvents must meet standards for purity, viscosity, evaporation rate, and compatibility with both solvents and PET materials. This not only enhances product quality but also ensures safety for both health and the environment. Moreover, depending on the type of commonly used PET ink solvents, businesses can flexibly apply them to increase the competitive advantage of their product lines.

Contact K-Chem Today – A trusted supplier of high-quality PET ink solvents in bulk at affordable prices. Get free consultation from our team of experienced experts!

K-CHEM VIETNAM CO., LTD

- Address: N6B Street, Lot F, Phu Chanh 1 Industrial Cluster, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

- Email: info@k-chem.vn