Top 5 common solvents for packaging ink and their considerations

16/05/2025

|

Industry news

Solvents are an essential component in the formulation of packaging inks, serving critical functions in the dissolution, dispersion, and application of ink systems. They affect the rheology, drying kinetics, and adhesion properties of the ink, influencing both the performance of the ink on substrates and the environmental impact of the overall formulation. This article provides a comprehensive analysis of solvents used in packaging ink formulations from a scientific viewpoint, focusing on their chemical nature, functionality, and environmental implications.

Chemical Functions of Solvents in Packaging Inks

Viscosity Modification

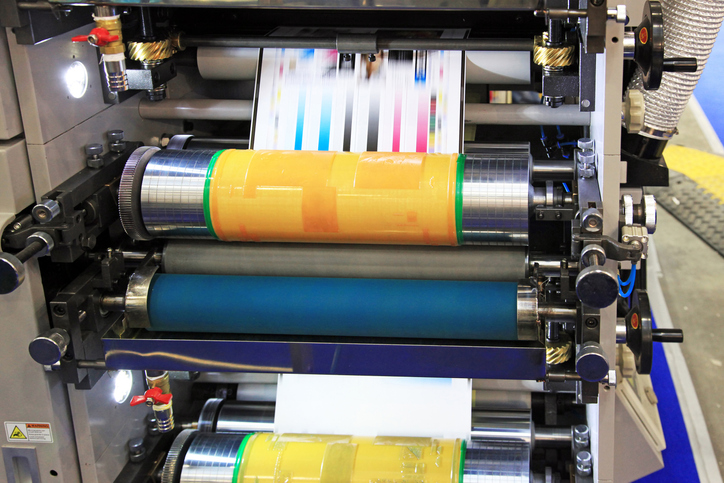

Solvents are essential in reducing the viscosity of ink, facilitating its flow and spreadability during the printing process. By adjusting the solvent concentration, ink viscosity can be fine-tuned to suit different printing techniques, including flexography, gravure, and lithography. The solvent must be selected such that the desired ink rheology is achieved, optimizing the ink’s behavior during the printing, drying, and curing stages.

Evaporation and Drying

The evaporation rate of the solvent is a crucial factor that dictates the drying time of the ink. Fast-evaporating solvents accelerate drying, which is critical for high-speed printing processes. The rate of evaporation must be balanced to prevent issues like ink smearing or insufficient adhesion. In solvent-based inks, drying is achieved through a combination of solvent evaporation..

Solubility and Dispersibility

Solvents are employed to solvate the resins and disperse the pigments in the ink. The solvent must possess the appropriate solubility parameters to effectively dissolve the resin, facilitating uniform distribution of pigments and additives. This ensures the stability of the ink formulation and prevents aggregation or flocculation of solid particles, which can result in poor print quality.

Adhesion to Substrates

The solvent affects the interaction between the ink and the substrate, influencing adhesion. A well-chosen solvent system ensures that the ink adheres adequately to various surfaces such as plastic films, paperboard, and metal foils. In some cases, the solvent also aids in enhancing the surface energy of the substrate, improving ink adhesion.

What Are Solvents in Packaging Ink?

Solvents are liquid substances used to dissolve or disperse the solid components of ink, such as pigments, resins, and additives. The solvent ensures that the ink can be easily applied to packaging materials by reducing its viscosity and improving its flow properties. Additionally, solvents help to control the drying time of the ink and enable the ink to adhere properly to different surfaces.

Types of Solvents Used in Packaging Ink

Aromatic Solvents

These are often used for their strong solvency power. Common aromatic solvents include toluene, xylene, and benzene (though the use of benzene is heavily restricted due to health concerns). Aromatic solvents help improve the spreading and adhesion of the ink, especially on non-porous surfaces.

Aliphatic Solvents

Aliphatic solvents, such as mineral spirits and naphtha, are less toxic than aromatic solvents. They are commonly used for applications where lower evaporation rates and safer alternatives are preferred. Aliphatic solvents are often used in combination with aromatic solvents to balance performance.

Alcohol-Based Solvents

Alcohols like ethanol, isopropanol, and methanol are widely used in inks for their ability to evaporate quickly, which accelerates the drying process. These solvents also improve the flow properties of the ink, making them ideal for fast-drying applications such as flexographic and gravure printing.

Esters and Ketones

Solvents like ethyl acetate, butyl acetate, and acetone are used to enhance the performance of inks, especially for quick-drying and high-quality printing. They are used in specific formulations where a high degree of solvency and excellent surface adhesion is required.

Water-Based Solvents

Water-based inks have gained popularity due to their environmentally friendly characteristics. Water is used as the primary solvent, with the addition of other co-solvents to improve performance. These inks are ideal for sustainable packaging solutions but often require additional considerations regarding drying time and adhesion.

The Role of Solvents in Packaging Ink Performance

Viscosity Control

The solvent controls the viscosity of the ink, which affects the ease of application, whether through flexographic, lithographic, or gravure printing methods. Proper viscosity is essential for achieving high-quality prints without issues such as smudging or incomplete coverage.

Drying Speed

Solvents also determine how quickly the ink dries on the substrate. Fast-drying solvents are essential for high-speed printing applications, especially for food packaging, where time constraints are critical.

Surface Adhesion

Solvents help the ink to properly adhere to various packaging materials, such as plastic, paper, or metal. They help in the dispersion of ink particles, improving the interaction between the ink and the packaging surface.

Environmental and Safety Considerations

As regulations around volatile organic compounds (VOCs) become stricter, the ink and packaging industries are increasingly moving towards greener alternatives. Low-VOC and VOC-free solvents are in high demand, and innovations like water-based inks or solvent-free inks are becoming more prevalent. These formulations help reduce the environmental footprint of the packaging industry, contributing to safer working environments and sustainability.

While some solvents like ethanol and isopropanol are relatively safe, others like toluene or acetone require careful handling, proper ventilation, and protective equipment during the manufacturing process to minimize risks.

Contact K-Chem today for a free consultation and discover how our high-quality thinners can improve your manufacturing efficiency. Get in touch now to learn more and receive expert advice!

Thinners are an ideal solution for time saving and labor cost. With outstanding benefits and diverse applications, thinners will be a great choice for manufacturers that want to improve work efficiency.

K-Chem is one of the top thinner manufacturers in the Vietnam market. Located in Binh Duong province which is very convenient to deliver to packaging and paints manufacturers in the South East area.

K-CHEM VIETNAM CO., LTD

- N6B Road, Lot F, Phu Chanh 1 Industrial Park, Phu Chanh Ward, Tan Uyen City, Binh Duong Province, Vietnam

- Tel: +84 274 362 0218

- Email: info@k-chem.vn

- Website: https://k-chem.vn